Videojet Labelling Systems

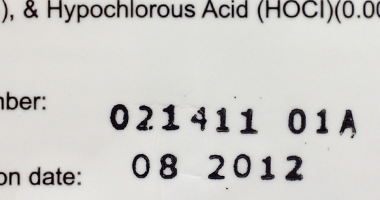

Labelling systems, often referred to as labeling systems, play a crucial role in the application of preprinted labels to a wide range of items, including products, individual packages, cartons, cases, and pallet loads. These systems are designed to uniquely identify items and promote a manufacturer’s brand image. Labels created by labelling systems can vary from basic black & white barcodes, 1D or 2D codes for identification, to intricate multicolor product labels that enhance brand recognition.

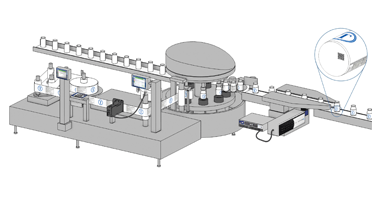

Labelling systems come in various designs and configurations, each tailored to meet specific requirements. Semi-automatic label printer applicators allow for manual label supply, suitable for individual product applications. Fully automatic labelling machines are seamlessly integrated into production lines, applying labels to products at production line speeds.

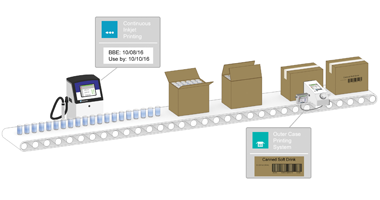

These labelling solutions encompass print-and-apply label printer applicators, which produce individual labels applied to packages or shipping loads. Case labelers not only record case contents but also meet the needs of distributors and retailers by placing labels with product ingredients, storage temperature, brand identity, shipping details, and more. They are capable of printing in the desired size and type while ensuring clear, readable characters and barcodes.

In a production line setting, labelling solutions are integrated with other line systems and automatically receive products or packages requiring labeling. Hand-held manual labelling machines offer on-demand label application, ensuring accurate identification.

Certain labelling solutions and the corresponding label machines are indispensable for providing products, packages, and pallets with unique identifiers and shipping information. Accurate labelling is crucial for the smooth flow of products through distribution channels. Pallet loads lacking complete and accurate labelling may face rejection and return at the manufacturer’s expense when they arrive at retailers’ docks.

Moreover, labelling systems and label machines responsible for applying brand labels to individual products and packages must ensure precise label placement, as wrinkled or off-center labels can have a negative impact on a product’s brand image. In some instances, these labelling systems incorporate vision inspection systems to verify proper label placement and label condition.

Related Articles

Suggested Solutions

Categories

Contact Us

New Equipment Sales:

+254-701-373789