Marking and Coding Solutions to Integrate with Semi and Automatic Cartoning Machines

Once a product has been sealed in an individual primary package, it is often placed in a carton with a number of other identical products. These cartons, with other cartoned products, are then placed in a larger shipping case for distribution. Finally, a group of cases is assembled to form a pallet load. This may be a unit load of identical products, or a mixed load of different products being shipped to the same destination.

This is a complex process, and it is essential that primary, carton and case packages be clearly marked and coded to identify them, both to track their progress through aggregation into a pallet load and subsequent distribution and to ensure that they arrive safely at their destination. A carton labeler plays a critical part in this effort.

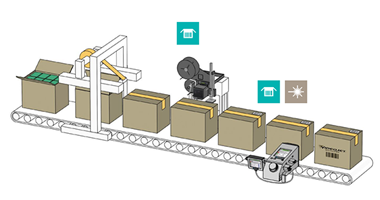

Printed carton labels can include both human-readable information such as addresses and product descriptions, as well as coded identification and tracking information, usually in linear and 2D barcode format. It is essential that barcode printing on cartons is clear and immediately readable to ensure that scanners throughout the packaging and distribution system can quickly identify the carton and move it through the process of being aggregated, palletized and distributed to its destination

The carton labeling machine applies the label to the carton, often while it is moving at speed along the production line. This often involves removing the release liner from a pressure-sensitive label before applying it to the carton. The carton labeler must complete the process and apply the label smoothly, avoiding creating wrinkles that may cover critical label information, all while not slowing the production process.

Carton labelers apply labels to various sized targets from small cartons to full pallet loads. As a result, they feature multiple methods for applying labels securely. These include blowing or tamping labels into place. For labeling pallets, carton labeling machines incorporate arms that extend from the labeler body to apply the label to the pallet surface. On cases, labels are sometimes applied around the edge of the case, allowing them to be scanned from either of two directions. Some carton labelers combine the functions of printing the label on demand and then applying it.

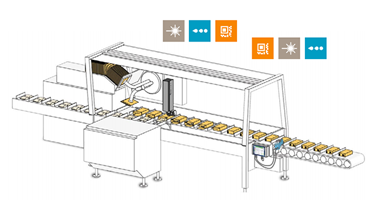

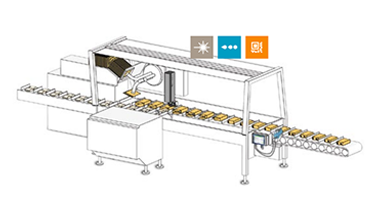

Cartoning machine is part of the larger family of forming-filling-closing machinery. It can be implemented in a fully or partially automated process.

The carton sealer is a packaging machine that can seal cartons semi- or fully automatically. Here, the carton sealer closes the carton not only by the folding the cover, but also when necessary, by using adhesive tape.

This wide variety allows companies to choose the system that works best for their operation. Cartoning machines often feed into a carton printer or labeller further down the production line.

Categories

Contact Us

New Equipment Sales:

+254-701-373789