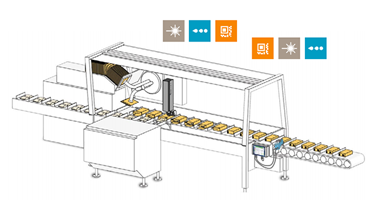

The carton comprises a pre-cut blank, pre-glued on the longer side and normally supplied flat, which receives the product by insertion from one end of the carton itself.

Inside the Carton

The cartoning applications require perfect co-ordination of multiple flows and can integrate very different types of material, carton structures, dimensions and shapes of product and sealing methods. The carton itself is formed from a basic flat form to obtain a three dimensional box or a tray, with complex folding or stapling operations. The product is positioned inside the box using, for example, a “pick-and-place” system or a robot. The box is then sealed and loaded into a separately formed carton.

Outside the Carton

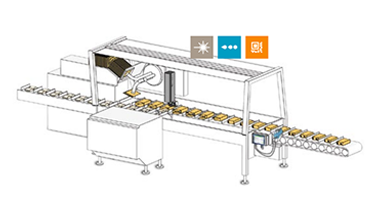

The cartoning processes are often co-ordinated with blister packing, joining, conditioning and other types of operation, thus integrating the infeed, sorting, and transport operations and other processes required in this procedure. In order to synchronise all these processes, precise positioning in each location is required, often at high speed.

Compatible Products

Bulk or pre-packed food products can be inserted vertically into cartons – such as dry pasta, cereals, salt, sugar, biscuits, frozen food, chocolates, sweets, flour, and all ranges of pet food. Chemical products, such as detergent powders or tablets, fertilizers, pesticides, bicarbonate, glue, grout and powder products in general, as well as liquids or other products already packed in bags, bottles or vials. Products such as metal or plastic hardware, plant seeds, traditional or innovative products, listed or not, are analysed and packed with more suitable equipment.

Related Articles

Suggested Solutions

Categories

Contact Us

New Equipment Sales:

+254-701-373789