Tobacco packaging facilities are among the most demanding coding environments, particularly with dust, often operating at the extremes of packaging line speeds. Additionally, cleanliness is paramount to assure the quality and consistency of the end products.

Videojet offers a proven range of class-leading laser, thermal inkjet and continuous inkjet printers which provide integration flexibility into multiple points on the line. Track and trace compatible, Videojet is able to provide solutions that can help safeguard your investment in a changing regulatory environment.

- Applications

- Line Integrations

- Documents

- Overview

- Soft Cup Pack

- Hard Pack

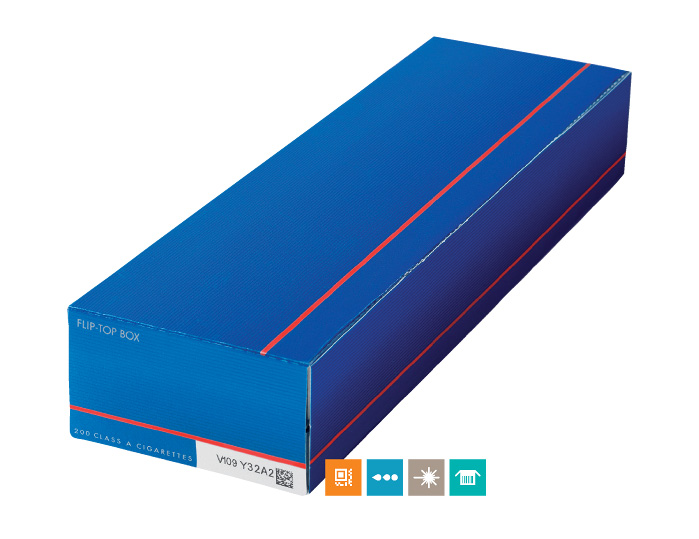

- Carton

- Pouch, Can, andOther Containers

- Case

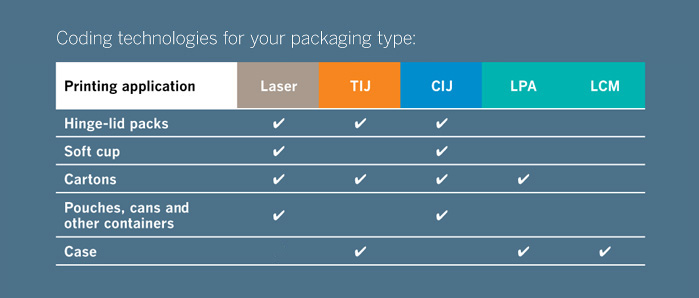

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

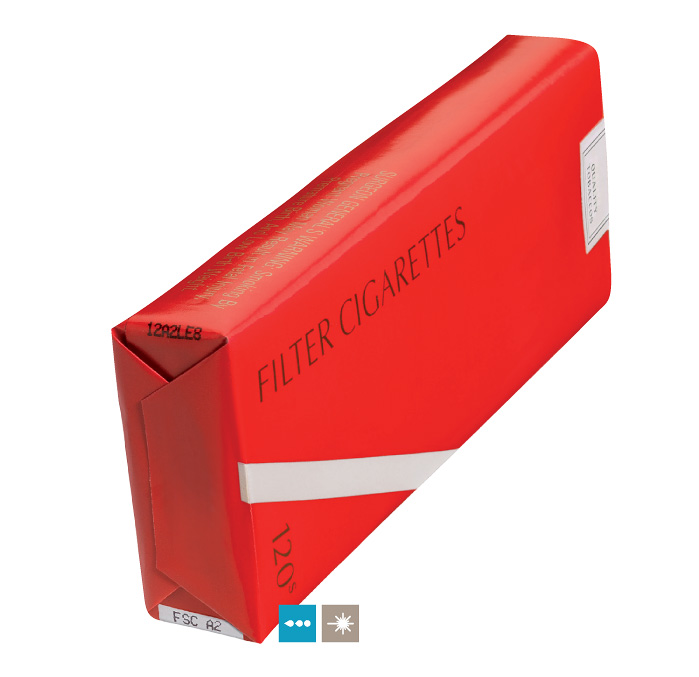

Flexibility to meet your production needs

Combining fast line speeds with multiple daily changeovers, soft cup packaging requires flexible coders that will not slow you down. Our printers are designed for built-in productivity and simple usability, meaning we can meet the throughput needs of your packaging line while helping to make life easier for your operators.

Laser Marking Systems

- creates permanent marks on a wide range of materials

- proven Codentify® solutions for soft cup applications using Videojet’s 30-Watt lasers

Continuous Ink Jet (CIJ)

- versatile coding method for irregular or curved surfaces

- Dynamic Calibration™ automatically adjusts to environmental changes to help ensure consistent print quality

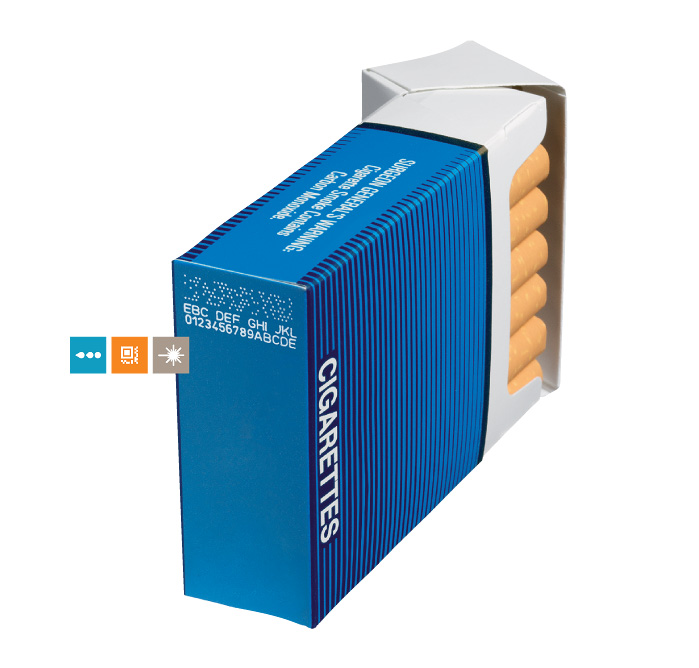

Keep pace with hinge-lid production lines

As packing equipment approaches 1,000 packs per minute and regulatory environments evolve, demands on print speed and print quality are compounded. Videojet designs printers and inks to meet the breakneck speeds of the tobacco industry.

Laser Marking Systems

- no inks or fluids required, thereby eliminating the potential of ink migration through packaging

- Videojet’s 30-Watt lasers can mark dotcodes and alphanumeric text at industry speeds

Thermal Ink Jet (TIJ)

- proven solution for multiple line codes and bar codes at high speeds

- no wear parts, minimising unexpected downtime

Continuous Ink Jet (CIJ)

- codes adhere to virtually all carton materials

- Ultra High Speed printers break the compromise between speed and code quality

Unlock track and trace capabilities

Videojet printers can print both human-readable and 2D codes to help enable track and trace for your cartons. Coders can be easily integrated into carton packaging equipment from leading tobacco OEMs, helping to minimise the footprint on your production line.

Laser Marking Systems

- clear, permanent marks help protect your brand from counterfeiting

- Videojet fume extraction systems help keep the production environment and marking lens clean

Thermal Ink Jet (TIJ)

- creates crisp, machine-readable QR, DataMatrix and bar codes

- Videojet’s long decap TIJ inks help ensure good code recovery

Continuous Ink Jet (CIJ)

- designed to perform in dusty conditions

- increase lines of content or create emboldened content at current line speeds using Ultra High Speed technology

Label Printer Applicator (LPA)

- produces high-resolution text, as well as 2D and linear bar codes

- Videojet’s LPA is designed for ease of use and low maintenance

Versatility to code on almost anything

As packaging innovation evolves in chewing and loose tobacco, Videojet has solutions to meet your needs and offers everything from food-grade inks for porous substrates to pigmented inks for difficult-to-code plastics.

Continuous Ink Jet (CIJ)

- portfolio of over 175 ink offerings supports a wide variety of substrates

- advanced Clean Flow™ printhead design reduces printhead cleaning frequency – even for pigmented ink

Laser Marking Systems

- clean, crisp codes that convey a premium brand image

- Videojet’s large marking fields help optimise power settings and avoid pouch burn through

Empower your supply chain

Legible case coding is the cornerstone of effective inventory management throughout the supply chain. Videojet technology can help in a variety of ways, providing high resolution printing for direct-to-the box and automatic label applications.

Large Character Marking (LCM)

- print high resolution bar codes, logos and other information directly on cases

- eliminates the cost, storage and management of labels and need for customer-specific pre-printed cases

Label Printer Applicator (LPA)

- high quality thermal transfer coding direct to labels

- automatic application offers greater speed, accuracy and error prevention than hand labelling

Thermal Ink Jet (TIJ)

- creates complex, detailed codes on paper-based substrates

- combining compact design and flexible communication choices, our TIJ printers integrate easily into your line

Hinge-lid/soft cup packer

Integrate before, into, or after your packer depending on application needs. With our extensive experience in tobacco packaging, Videojet has the know-how to meet the code, speed, and footprint requirements of your application.

Cartoner

Regardless of your carton packing configurations or coding preferences, Videojet offers automated solutions and seamless integration into your production lines. This helps you deliver high-quality codes where you need them, when you need them.

Case packer

Videojet end-of-line technologies provide class-leading, consistent print quality on secondary packaging materials. Whether you require 2D codes for track and trace or larger prints for generic case coding, Videojet has a solution to meet your needs.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

Contact Us

New Equipment Sales:

+254-701-373789