Sorry, but the DN50A and LN100A are no longer available – we recommend as an alternative product the Videojet 7510 and our fiber laser marking systems which will fulfill your needs. If you need any support don’t hesitate to contact us.

Laser Engraving System

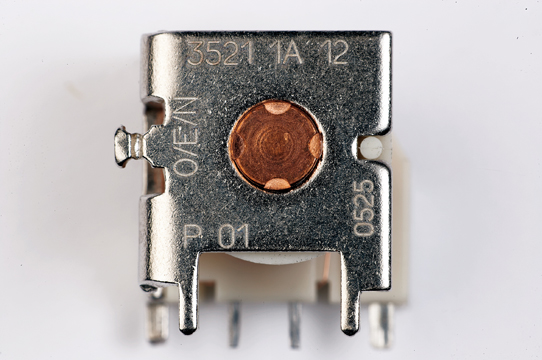

Designed in conjunction with our sister company Foba Alltec, the Videojet DN50A and LN100A are Nd:YAG lasers designed to meet the most stringent laser marking requirements for throughput, flexibility, user-friendliness, reliability and quality. The 50 Watt DN50A is suited for applications involving engraving, a colour change, colour removal or annealing marking at impressively high resolution. The 100 Watt LN100A is suited for engraving applications at higher power levels for greater throughput.

- Specs

- Benefits

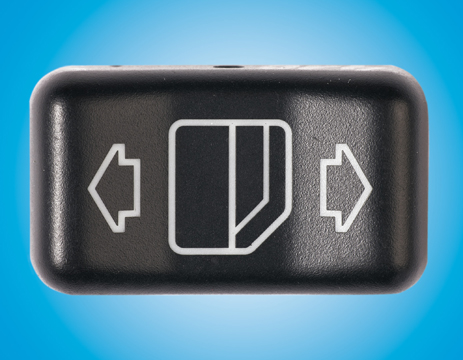

- Applications

- Documents

| Specification | DN50A | LN100A |

|---|---|---|

| Laser Tube | Nd:YAG | Nd:YAG |

| Maximum Power | 50W | 100W |

| Laser Cooling | Liquid, Internal source | Liquid, External source |

| Maximum Print Speed | 1300 characters/sec | 1300 characters/sec |

| Maximum Line Speed | 900 m/min (3000 ft/min) | 900 m/min (3000 ft/min) |

| Environmental Protection | IP44 (Laser Head), IP42 (Laser), IP22 (Marking Head) | IP44 (Laser Head), IP42 (Laser), IP22 (Marking Head) |

| Beam Output | Digital high-speed galvanometer scanner | Digital high-speed galvanometer scanner |

| Laser Source Expected Life | 10,000 – 15,000 hours | 1,000 – 2,000 hours |

| Laser Wavelength | 1.064 μm | 1.064 μm |

| Focal Distance Options | 100 mm (3.93 in) – 420 mm (16.53 in) | 100 mm (3.93 in) – 420 mm (16.53 in) |

| Maximum Mark Window | 498.5 x 361.5 mm (19.62 x 14.23 in) | 498.5 x 361.5 mm (19.62 x 14.23 in) |

| Standard I/O Connectivity | Ethernet, RS232 | Ethernet, RS232 |

| Standard User Interface | Touch screen | Touch screen |

| Optional User Inteface | PC, Handheld, Software | PC, Handheld, Software |

High speed marking performance for greater productivity:

- Capable of high quality marking at line speeds of up to 900 m/min (2950 ft/min) and 1300 characters/sec

- Efficient production of marking jobs with text, machine-readable codes, graphics or other variable data

Meet the needs of a wide range of application solutions with superior laser beam quality and control:

- The laser beam parameters can be adjusted to suit the job requirements for the best marking quality

- Powerful software lets you create messages with automatically updated content, symbols, graphics and languages

Highly flexible integration:

- Compact system design and innovative beam deliver system simplifies integration into production

- Capable of being completely controlled by computer for use in fully automated production lines

- Adaptable communication system makes print job development simpler and capable of being completed off-line